Properly managing silicon can promote high quality and yield

Silicon is a vital component for water and nutrient balance in plants. Deficiency symptoms are only observed during stress events, in which plants are more prone to damage from frost, heat, drought, lodging and salinity. Understanding the silicon needs of your system and how to properly fertilize to maintain sufficient concentrations is essential to produce high-quality, high-yielding crops in an increasingly stressful environment.

Silicon Requirements

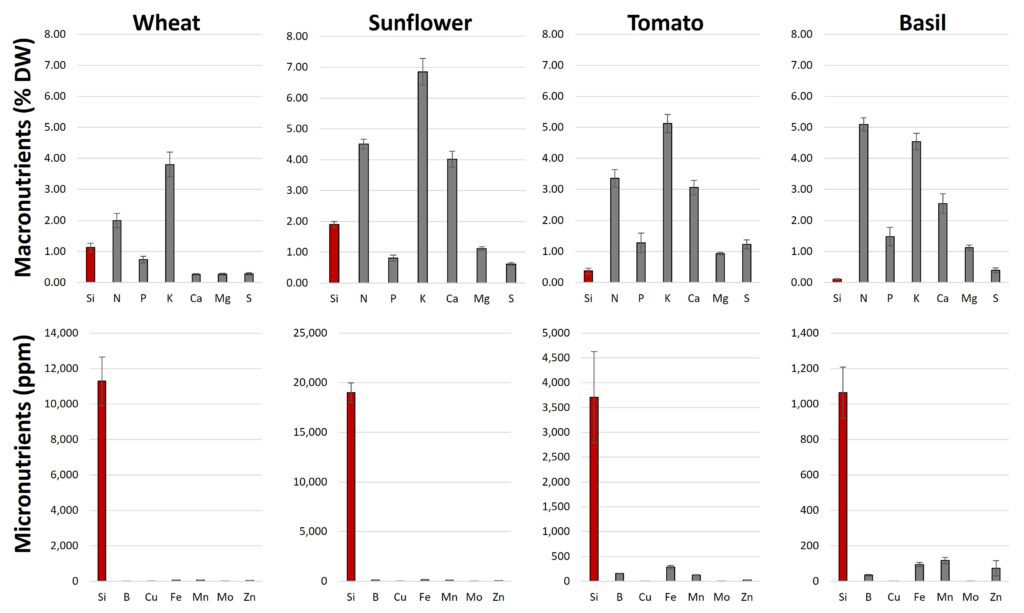

Let’s begin by looking at silicon requirements for different crops. If you’ve read the literature on silicon, you’ve likely came across the terms “low” and “high” accumulators. Unfortunately, these terms are not relative to how we describe any other nutrient. A high silicon accumulator designates a plant that accumulates more than 1 percent Si in its leaf tissue. These concentrations are similar to or exceed nitrogen and potassium! All other plants — those below 1 percent — are then described as low silicon accumulators, even though most concentrations are within macronutrient ranges.

Notice in Figure 1 that grains (corn, wheat and rice) accumulate silicon in the range of nitrogen and potassium, while other plants, like tomatoes, accumulate silicon to the level of sulfur and magnesium. Taking this a step further, if we compare silicon to other macronutrients and micronutrients in plant tissue, we clearly see that its concentration is significantly higher than B, Cu, Fe, Mn, Mo and Zn (see Figure 2).

Basil is a great example — it has a lower silicon concentration than wheat or sunflower, yet compared to its own nutrients, silicon is slightly lower than other macronutrients and significantly higher than any of the micronutrients. Clearly, crops have a high silicon removal rate that over time can have a significant impact on the production capabilities of our fields.

The Source, Rate, Time and Place for Si

Most farmers or growers may not think about silicon as a nutrient when it comes to producing high-quality, high-yielding crops. Applying the principles of the 4Rs for nutrient management — the right source, right rate, right time, and right place — can help us understand how to use and benefit from silicon fertilization.

Using the right source of silicon is vital. While silicon makes up 28 percent of the mineral fraction of most soils, or 280,000 ppm Si, of that concentration, only 0.0003-0.0017 percent (3-17 ppm) is in the plant-available form of silicic acid. Silicon fertilizers in the U.S. are labeled with “% Si,” referring to the silicic acid fraction of the material. This is the right source — the one you want to ensure is provided to your crops.

Also be aware that the available silicon pools in the soil solution can quickly deplete, especially during the production of high-silicon-demanding crops like wheat, barley, corn, cucurbits and sunflowers. Silicon removal rates per acre are especially high when harvesting whole plants like sorghum sudan, corn silage or wheat and cereal straw. This creates a silicon deficiency for successive crops, often leaving fields more prone to environmental damage, such as frost, drought, heat, lodging, etc. Maintaining adequate plant-available silicon pools is essential for protecting yields and quality.

Just as important as the source is the right rate of silicon to apply. Soil testing to predict the silicic acid potential of the soil is an option to start tracking silicon availability. Depending on the extraction solution, the target values for silicon in the soil will change. For instance, CaCl2 extraction detects the amount of water-soluble and readily available silicic acid, while a 0.5M acetic acid extraction includes the above and a fraction of the exchangeable Si. This is one reason why there isn’t a set deficiency range for silicon in soils — depending on the test method, that value could be as low as 30 ppm for the CaCl2 method or as high as 100 ppm for the 0.5M acetic acid extraction. However, having the information and tracking the value over time can help determine the impact your fertilization plan has on the Si fraction in the soil.

Determining the correct application rate can also be tricky. Many of the products available on the market today have a wide range of percent Si and may either be a granular or liquid. For granular products, the application is based on the silicon release rate of the material over time and can range from 100 pounds up to 2 tons per acre, depending on the material. Products with a higher bulk density tend to have application rates at the upper end of the range. Liquid products also can vary in the rate range, from just 0.1 fluid ounce up to 5 fluid ounces per gallon. This range depends on both the percent Si and the stability of the product in the final mix. While there is no phytotoxicity for overapplying silicon, be sure to follow all label rates for the intended crops.

The right time for silicon application is still under debate. Granular material can be applied either in the fall or spring, prior to planting, and tends to have residual effects one to two years following application. While in the past I have not recommended silicon fertilization prior to emergence, there are some promising data showing benefit from mixing in liquid silicon products with a starter fertilizer. Silicon is used by the plant during rapid growth or in response to stress events. Applications of nutrients or pesticides throughout the growing season are usually in anticipation of lush growth or prior to disease or stress. These are the perfect times to include silicon in either the tank mix or fertilizer spreader. As a warning, not all silicon formulations are stable with tank mixes or certain products, so be sure to follow the label instructions or advice of the distributors. And, as always, a simple jar test prior to mixing up a large volume is always recommended.

This brings us to our final R, the right place. Fortunately, like other nutrients, silicon can be absorbed through either the root system or leaves. Granular material can be incorporated into the entire field or side-dressed. Liquid products can be applied to foliage or fed to the roots via irrigation or fertigation lines. Root applications help produce strong root systems that enhance water and nutrient balance in the plant, maintaining yield under moderate stress events. Foliar application can also help support the growth of a healthy root system and provides silicon directly to the leaves, allowing for protection to excess water loss and enhanced photosynthetic activity. Unlike other nutrients, silicon does not have a negative environmental impact and is an important nutrient not just for plants but for microbes and animals.

As we search for ways to improve production or to recover declining fields, silicon nutrition should be one of the first parameters to check. Silicon deficiencies require higher inputs of nutrients, water, pesticides and insecticides, as the plants are missing an important macronutrient. Applying the 4Rs for silicon nutrition will improve the performance of your fields or gardens, leading to higher quality and yield of your crops or produce.

Dr. Wendy Zellner is a plant physiologist and is the founder of Zellner’s Research Solutions, LLC. Contact her at ZellnersRS@outlook.com.