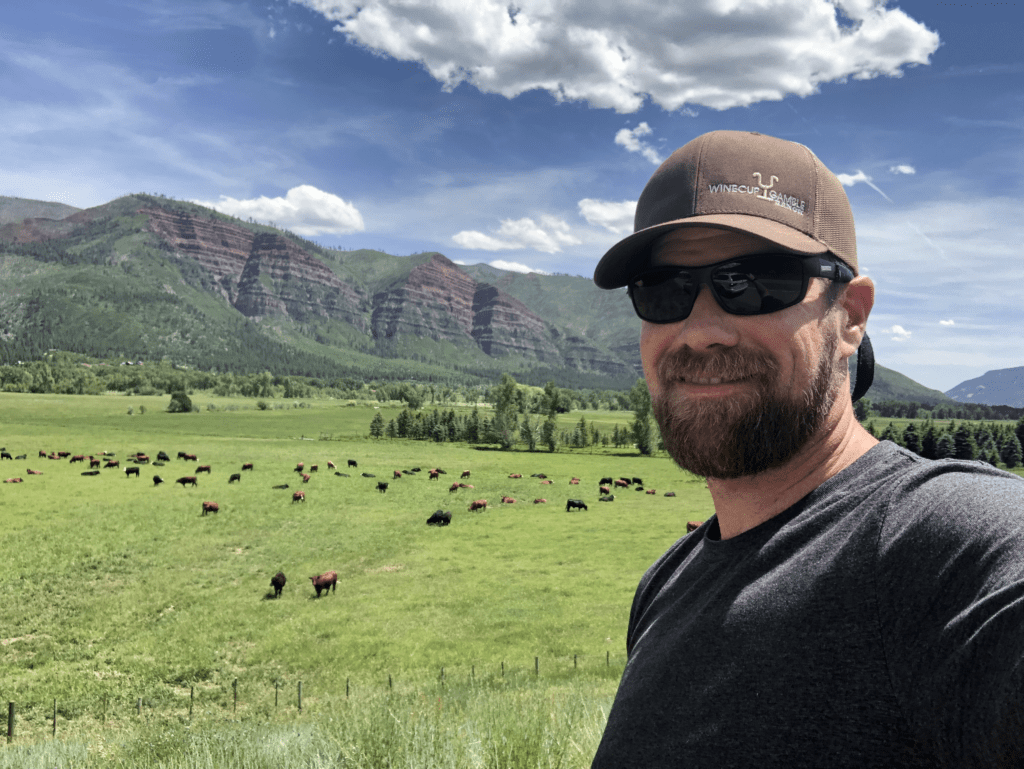

Supply chain expert Ian Chamberlain talks about scale, definitions and what issues the regenerative movement should be contemplating

Acres U.S.A. Can you describe a bit about your background and your context?

Ian Chamberlain. Sure. I grew up here in Durango, Colorado, and like most Durango kids, I thought everywhere must be better than this place. I found out that that’s not really true — which is why I’m back here now.

I graduated early from high school and left, and my big thing was skiing, so I went to try and ski big mountains, and then I spent the next 15 years trying to figure out how to get back to Colorado or to Durango or somewhere like it. I ended up in northern New Mexico working for a while on a farm. A buddy of mine in college had gotten a job for a lady who’d just bought a farm in New Mexico, and they were planting some trees, and I was in Gunnison, Colorado, only four or five hours away from the ranch. He said, hey, come help me plant some trees. And I showed up and basically never looked back. That was the summer of ’99.

I didn’t grow up in ag — my mom’s a realtor and my dad was a retired merchant marine — and we all argued over who had to mow the lawn. I’d never had a garden and had a really disconnected relationship — as most people do — to food and the food system.

And then I had a series of events in my life that made me reevaluate the direction I was trying to go — what was fulfilling and not fulfilling — and as I let myself get more exposed to agriculture, it became really evident that it fit in with who I am. It clicked — a lot more than college or any of those other experiences I’d been struggling with.

Acres U.S.A. That farm in New Mexico — what kind of stuff were they doing there?

Chamberlain. So, it was a second residence for a wealthy family. It was a 15-acre specialty crop farm, and it was certified organic, and they did root crops and echinacea and lavender, and they had a distillery on site where we distilled all kinds of essential oils. We sold at the Santa Fe farmers market. And we also did lots of cut flowers. The owner was a botanist — a florist — she was independently wealthy, so this was a second home. But they really wanted to make it a viable working farm.

It was this really unique situation; we got to learn a lot — they were really into education, so we went to all kinds of different seminars and classes. This was in the early 2000s, so people were talking about sustainability and organic. And then one day she showed up with a van full of Angora goats, and we were like, “What are we doing with these?” and she said, “They’re gonna eat the weeds, and then we’re gonna harvest their fiber, and this is gonna be great.” My partner at the time was an artist, and she got really into fiber art.

So, we ended up opening a wool mill on the property. We had a large herd of Navajo churro sheep, which are specialty fiber sheep — we had about 200 head at one point. And then she had all the goats. So we did the sheep and the goats, and then we had a processing service for other folks — all specialty fiber growers. It was a cool operation — growing crops, doing some value-added stuff, and then having this wool mill. And it was all Mexicans and people from the South that worked with us, and they were our teachers. I had no history at all, and my partner didn’t either, but we were passionate about it.

All of our sheep had horns, so every time an animal would get its head stuck in the fence, the people who worked with us were like, “Oh, man, sorry, but go start a fire — we have to have a barbecue!” I was the boss, but I was new, so I was like, “Okay, I guess that’s what we have to do.” But then after the third or fourth time, I was like, “No, we can just get its head out of the fence — it’s fine.”

But through that experience, we were butchering all these animals on the farm and eating them, and I realized that the byproduct from our wool was meat. So, we started a small meat brand to accompany the fiber endeavor. And that summer, one of our customers approached us at a farmers market and asked us to come run his ranch in Chama, New Mexico, which is north of Santa Fe. It was 3,000 acres with these big Scottish Highland cattle and four wheelers. That sounded great, so we went there and ran his ranch for a while.

And he wanted us to start a beef brand. Chama is a little closer to Durango, and a family I grew up with had just opened the USDA meat processing plant near Durango. So I went and started working with them to start this brand, and my partner wanted to go back to school, and there’s a college in Durango, so we ended up back in Durango.

Long story short, the plant said, “Hey, will you come run the farm and the main plant for us?” And so I got into helping them on the processing side. We were still raising animals and putting up alfalfa on about 360 acres, so I was still getting my outside time — driving the tractor and running animals.

Acres U.S.A. The first farm — were the people who owned it actually operating it, or were you the managers?

Chamberlain. No, we were the caretakers and the managers. They would be on site every six weeks or so. Anytime the wife had time, she’d be on site. They actually got divorced about two or three years in, and she spent a lot more time on the farm after that. She was really into it, and he was a little less into it. They’d just come down and say, “Here’s our vision and here’s our credit card; try and make it happen.”

But he was an investment banker, so we had to have quarterly P&L reviews. So there was an element of trying to make it a viable business, and that continued even after their divorce. She wanted to try and make it profitable, but whenever we’d say, “If you want us to do this, that’s going to be at the expense of potential profit,” she’d always say to do it. She paid really well — a true living wage. She was really generous in that regard. I recognized early on that this was a very unconventional agricultural endeavor.

Acres U.S.A. I’ve had the experience of working on a farm that was owned by a really rich guy, and it had its issues. He wanted to do all this stuff — he wanted to be regenerative; he wanted to pay living wages in this super rural, poor, part of the state; he wanted to help young farmers. But he also wanted to make a profit. We realized pretty quick that you can make a profit, but it’s really hard — we didn’t at that farm — make a profit while doing all of those other things too. I’d be really interested in hearing stories of places where this kind of thing actually works.

Chamberlain. Yeah. The second guy I worked for was one of the founding members of Verifone. So big time cash. Obviously a brilliant mind.

Acres U.S.A. But being brilliant in one thing doesn’t mean you’re brilliant in everything — particularly agriculture. That’s the problem.

Chamberlain. Exactly. He liked the ranch, but it was one of those things where, for example, we’d get like two hours of his time, and to me — I mean, this is my life. I was so immersed and involved in something that wasn’t actually mine. But it really helped me shape my perspective of stewardship, and that was really good. I didn’t own anything I took care of for decades. Along the way there was a lot of resentment for that, but also real learning for me — that we don’t own any of this — we’re not taking any of this with us. You can put a fence around it, but it’s all really about stewardship.

It helped me craft the idea that no matter what I’m doing or where I am, to give it your all and do your best — to leave it in a better condition than you found it. It’s something I just didn’t get as a kid growing up in town. My parents made me earn every penny, and I really appreciated that. But that journey of working other people’s land and trying to make their vision a reality — you have to find your fulfillment in that somewhere, or else you’re not going to last.

Acres U.S.A. So you got to this processing plant; what size facility was that?

Chamberlain. Very small — about 10,000 square feet. We did all species — pork, sheep, goats, beef — and we did it from slaughter all the way to beef sticks and hotdogs. We fully fabricated down to the retail level and were helping farmers build brands.

I think one of the biggest things I was proud of was working with the state of Colorado on the farms-to-school project. We ended up having 17 or 18 school districts, and the program was providing 100 percent of their beef from local sources, processed in local plants. Even though we were small, we were able to have an impact within our local community.

And then we’d shut down for two weeks and do all the county fair stuff. We’d do 400 or 500 animals for the kids, and they’d come in and do carcass contests. The folks that owned the plant had very successful off-farm businesses, and this was a community resource. They were very business conscious, but they also decided this wasn’t about making a profit. This was about supporting the community. It was a real passion project for them to support folks trying to do small-time agriculture.

Acres U.S.A. That’s great. How long were you there at that plant?

Chamberlain. I did two different stints. I was there for six or seven years, and then my partner and I decided to go out and try to farm on our own. We had showed up in the early 2000s, and then in late 2007 we bought a farm Washington state, 10 miles south of the Canadian border. And I think it would have actually been successful if it hadn’t been such bad timing, with the financial crisis. Before we knew it, we were completely upside down.

And at the time, also, my mom actually had brain cancer. So I came home to take care of her for a while, and she had successful surgery and has been in remission since. So I had left the main plant, had done about a year in Washington, built this farm that didn’t really work out, came back to Durango be with the family, and then I took the job back at the meat plant and worked there for another three or four years.

By 2014, we were in deep with the people that own this plant; they built us a house with a commercial kitchen, and they wanted us to stay to run the meat plant. But a buddy had put me as a reference for a job with a guy who had gotten funded by private equity to start a grassfed beef company in California, but he was gonna be processing in Denver. And he called me, and I gave my friend a great reference, but they could never finalize negotiations. So the guy called me back and said, “Hey, we had such a great call — send me your resume.” I wasn’t really looking for another job. But long story short, I felt like this job was the culmination of all the work I’d done — caretaking and then working in this inspected meat plant — and they needed somebody who could go out and help sell this product but who also understood carcass utilization and beef cutout. He had a fairly successful brand of South American grassfed beef, but he realized early on that it was because he had people on the ground at each step of the supply chain.

So, we went up to Denver and lived there for three or four years running that program. That was my first experience at a bigger meat plant. We killed at one plant and did fabrication at another. And they sent me to South America to look at the operations down there, and that totally blew my mind. I was the guy who was always against imports and who supported local food systems, and here I was going down and seeing these global operations. But I realized that these were people just like me, who were well-intentioned people trying to do good work. It totally expanded my vision to a more global perspective. I got to travel to Australia and New Zealand and throughout South America working in supply chains — mostly beef — and was able to learn how stuff moves and how the system works.

Acres U.S.A. I want to talk about that — about scale. Lots of people these days talk about how small scale is the only way that can really be regenerative. Do you think it’s necessary to be small in order to be regenerative?

Chamberlain. No — like Will Harris says, we can all recognize there’s a limit to how much you can scale a regenerative system, but you can replicate it as many times as you want. Conventional agriculture can kind of spin that on its head — the people who started out with a feedlot probably had 1,000 head, and that first guy was like, “Wow, look at all these animals!” But now there’s 100,000 animals at a feedlot at one time. It took evolution to get to that extreme. I think we’re seeing that regenerative is at the beginning of that evolution, and people are saying, “That’s as far as you can take it” — until somebody takes it further. Eventually there’s going to be a limit. And at that point, great — start over and replicate it. What I think Will Harris is referencing there is the complexity of the systems we’re operating with. There’s a limit to how big we can take them until it’s just overwhelming.

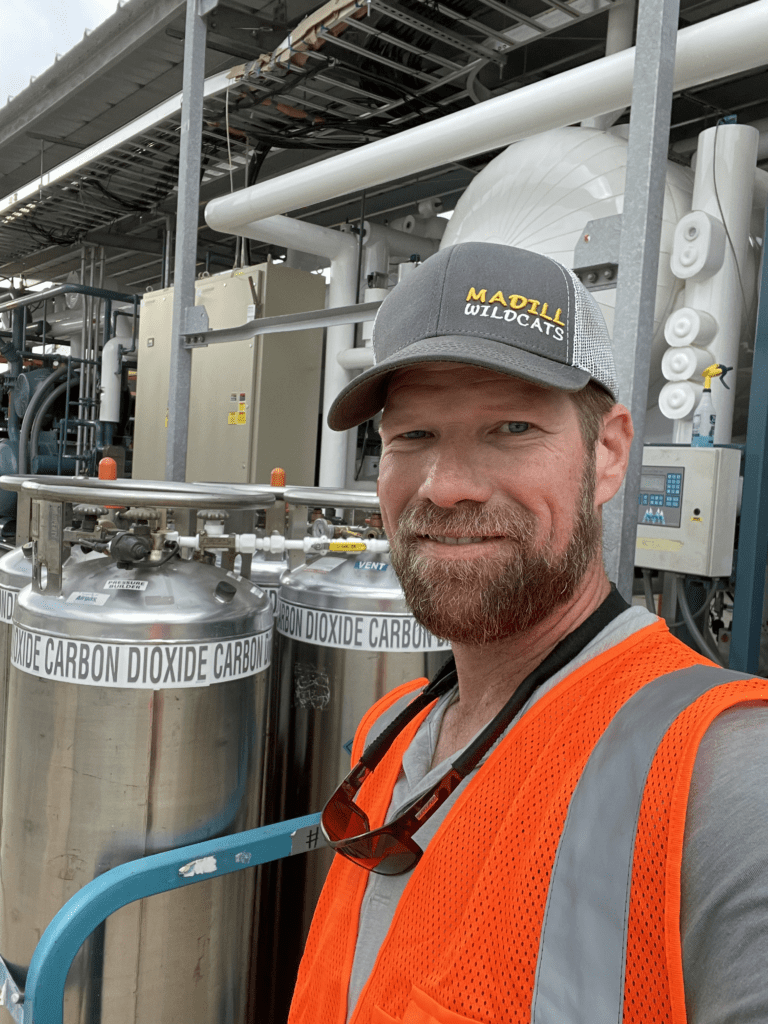

The last job I had before RFSI was my exploration into the commoditized, seriously scaled food system. I worked for this international company — European and Australian — and they sell offal all over the world — 1,000 containers a month. We built a plant in southeast Oklahoma that can freeze a million pounds a day. I was attracted to this job because it was supply chain optimization at scale — carcass utilization across multiple programs. We’d ship container loads of tripe — container loads of individual SCUs or items. When you’re operating at such a scale, you can’t do 35 different SCUs where one of them is only 10 pounds a week and another is 10,000.

It became really evident to me working at this really commoditized, super-scale container level that it’s hard to interject regenerative perspective into those types of operations. But you could get to those levels through aggregation — you could get those end results, but it’s just going to be through a different way. Right now we aggregate on the front end with 100,000-head feedlots. We’re aggregating at the wrong end of the supply chain. Instead, everybody should operate at a more reasonable, regional, localized scale, and then figure out through the supply chain to aggregate and consolidate all the stuff the regions can’t consume and that needs to go out on a more national level. We’ve just turned it on its head.

Acres U.S.A. There are all these conversations about what “regenerative” means, but what is a regenerative supply chain? What does a more regenerative supply chain look like?

Chamberlain. I think there are two versions of it. We used to live in this super small microcosm where the producer was all-in on these practices. If they can find a way to be more regenerative, they do it. They see the light and there’s no way they’re going back to conventional agriculture. But the constraints and some of the hurdles they have are going to limit them to a certain scale.

But there’s another conversation happening at scale with big corporates and big institutions, and they’re picking and choosing different regenerative practices to implement in their conventional models. I think we’ll see incremental change through that system. We’re seeing companies like McCain, which sells McDonald’s all their potatoes — they’re talking about the regenerative practices they’re using. General Mills is talking about it. I think that’s a good thing. I know there’s a risk of greenwashing. We’re not talking about companies that are in the red — these are very successful companies that are making real revenue and profits. They might make a list of 20 practices and principles they could put into place, and can afford to do so, but they might only pick three of them. Why? This is all an evolution — it’s all a cycle. How hard do we push to see this change happening faster?

On the other hand, the people that are 100 percent all-in, running their 100 head of cattle regeneratively, rotationally grazing them — they’re not really, in my experience, getting the premium necessary to realize all that additional work, and all that additional value that they bring to their community, and their use of that animal’s life. So, there’s a real disparity in the return for somebody that’s all-in doing these regenerative practices — they’re just not seeing the premiums that they’re going to need to make it a viable, scalable business.

Acres U.S.A. How do they start to realize that premium?

Chamberlain. Well, I come from a really skewed perspective. I work with Regenerative Food Systems Investment, but I also consult through a company I founded called Pastured Proteins, and I’ve seen it firsthand at almost every place I worked at for about 10 years. We had a director of procurement, and we had a CFO, and we had logistics, etc. Were all of those positions 100 percent warranted at the scale and size of business we were at? Maybe not then, but we wanted to get there. So, maybe there’s a shared resource model amongst some of these brands that are in transition to get to scale.

We’re seeing some of that happening through COVID, where a growing company can, say, rent a CFO or whatever position they need. And I’m in conversation with a group right now that’s looking to be a supply chain management group for regenerative systems — not just to come in and be the consultants who say, “Do this to get better soil carbon,” but saying, “Do this, and these people will buy your products.” They want to help companies be really connected from end to end and to help them know the standards.

So, some of it is standardizing what is regenerative. For some people, it’s soil carbon; for some people, it’s some social standard — and those are completely different ends of the spectrum. We need a baseline understanding of what we’re talking about when we use the term regenerative. And then I think we have to make sure that we’re optimizing the supply chain in every way we can to take advantage of links in the commodity supply chain that we can just dovetail into. A warehouse doesn’t care if it has organic meat on the shelf or conventional — they’re gonna charge the same per pound or for that space. Same thing for a trucking company. But you’ve got to be at truckload quantities, or you’ve got to be at some kind of increment that makes sense to the current supply chain, from a processing perspective.

Acres U.S.A. Yeah, and the warehouse itself doesn’t care, but the owner of the warehouse might, if they have to keep those two products separate — if organic has to be stored in a totally separate place, especially if it’s not packaged. Do you think that sometimes holds things back?

Chamberlain. Yeah, I totally agree. Especially coming from the meat industry — it’s one of the most highly regulated spaces in the country, as it should be, from a food safety perspective. But you have to ask yourself, “Why is it okay for all this commodity meat and conventional meat to commingle and not be traceable, but once I want to make a claim, I’m the one that then has to validate it?” I think these are systems that we should have across the supply chain, from a public safety perspective. I think these are things that are not being addressed, because I think there’s been influence to loosen regulation in that regard.

Acres U.S.A. Right — crony capitalism — not real capitalism.

Chamberlain. Exactly. Part of it is maybe making everybody play by the same rules. You want to say it’s commodity — great — keep it separate from everything else, just like the certified farmer has to.

Acres U.S.A. What do you think about the argument that regenerative certification shouldn’t just be on the back of the farmer — that the supply chain itself should require regenerative certification? And what do you think a certified-regenerative supply chain could look like?

Chamberlain. I think there’s huge potential there because all of these big corporations, and even small ones, are pushing for everyone to have these new ESG standards and Scope 3 emissions and whatnot. I don’t have any data for this, but in terms of how many touch points there are and how many times our food is moving, and the amount of resources it takes to process and fabricate and package it — I think there’s just as much opportunity to make improvement in those segments of the supply chain as there is on the farm or the ranch.

I would love to see somebody come in and be able to fully assess those types of supply chains. But they’re really complex. And a lot of times a truck doesn’t go from point A to point B, right? It goes ABC to Z, but not the same way every time. I think it could be challenging to have a true assessment. But I think we have to try, because there’s a lot of improvement we can make over all of those sections of the supply chain.

I just think of how UPS, when digital mapping came out, simply stopped turning left, and they saved so much time and money. It can be something as simple as that, that we could implement in existing supply chains. The disadvantage of not operating at scale through each section of the supply chain — I think there could be a huge reevaluation of the impact we could make. But how do we get there? Consolidation and aggregation of some of these programs is one way.

I was at a meeting years ago with some Australians, and there was an American guy there who was so adamant about us grassfed and regional production, and he stood up during the meeting and said, “I don’t support anything that supports imports. And I’m not going to participate in this conversation.” And he left the meeting. I had the opportunity to talk to him about it later, and I told him that I really appreciated his perspective, and I commended him on how he was sticking to his guns and how strongly he felt about this. But I encouraged him to understand that we’re doing exactly what the conventional guys want. We’re fighting over less than 3 percent of the meat market — versus going after some of the 97 that the conventional producers own. We’re sitting here arguing over grassfed from here or there or whatever, when they’re selling hundreds of millions of pounds of commodity meat that’s out there for the taking. We’re standing out in the middle of the street punching each other in the nose while JBS and Cargill are laughing about it all the way to the bank.

So, I think that there’s a big opportunity for the players within the attributed space to play together and to really do consumer education within marketing. People say that negative marketing doesn’t work. Well, how come when you walk into a specialty food store, it’s “No MSG. No GMOs. No this, no that.” It seems like there’s a lot of no’s going on over all of our packages. We need to be more about “Yes, this is what we’re doing.”

I was at a regional conference last year, and the big question during the main breakout was “What is regenerative?” All 50 people in this breakout session had an opinion, and when it finally got to me, I said, “Look, I think we’re asking the wrong question. What isn’t regenerative? If we can just have the consumer understand that — what’s not regenerative, versus us having to make the case about what is regenerative — let’s have that conversation. What’s regenerative about Coca Cola? About Walmart? Turn it on its heels and have them talk to us about why they should we be supporting us.”

I’ve been in the attributed space for so long, which is vocal minority of people who want to know the name of the animal they’re eating — all while the majority of people live in food deserts and are eating at a 7/11. We’re asking the wrong questions, and we’re servicing the wrong communities of people with this regenerative conversation. I’ve had a complete shift of thinking on this. I went from doing private-label brands that get sold at premiums — $35-a-pound steaks at farmers markets — to now wanting to know what we’re doing to get healthier food into convenience stores and schools and hospitals and the military.

We’re asking the wrong questions; I think that’s really the problem. And they’re laughing at us because we’re chasing our tails, and we’re fighting each other.

Acres U.S.A. How do you get how do you get people to ask the right questions? What’s the process of changing that?

Chamberlain. I think you guys are doing it already. Acres is asking the right questions and is standing strong on those principles — that organic and sustainable methods are the way to go, and here’s why. There are certain communities that want all the science behind it, and there’s a certain feel-good community. We’ve got to hit all those angles.

I also think that we need a concerted effort of flipping the script in terms of brands — not having the BS cow eating grass out in the field that even Smithfield has on their label. It takes pioneers; it takes some courageous people to get out there and do it first and start that conversation.

But it’s scary, especially in the current economic climate. We have the luxury to have this conversation. I’ve got plenty of food in my refrigerator. We have to also be conscious of what conversations people are having. You and I care about Roundup use, and people with cancer probably do, but the common consumer? Probably not. It’s about speaking to your audience.

Acres U.S.A. What about your current work with RFSI? What the case for investing in this space? And what are some of the challenges with that?

Chamberlain. There are a ton of challenges, but I think it’s a lot easier to highlight the opportunities right now in the ag tech space, and food tech. We’re seeing a lot of young people that are excited and interested in being a part of agriculture in some way. And there’s this big explosion in CPG brands. There are people excited about food.

At RFSI, we’re trying to connect the dots out there. There’s a lot of folks on both sides of the aisle, and we have the opportunity to be heads-up listening to everybody and looking around for opportunities. Most folks are head down, plugging away at their work, laser focused on their missions, and using their visions and values to guide that. So we’d like to operate as folks that are helping connect the dots and encouraging that networking and conversation. And that’s what we do through the forum —- trying to encourage the conversation — but beyond that, we’re really looking to connect the dots so these opportunities can be acted on more quickly and so that people aren’t missing out on them. So many people are having the same conversation, just in different ways. How can we bring everybody together?

We do that through the newsletter, through our forums, but we’re looking for new mechanisms and new ways that we can act as that bridge to help connect people. There’s so much excitement and interest to get money into regenerative, but people need to feel confident and safe, and we need to mitigate risk as much as we can. This is a new frontier for investment, and it doesn’t meet a lot of the previous litmus tests — there’s a lot more risk and unknowns in agriculture in general, but especially when you start to apply new principles like regenerative that don’t have a lot of existing data. People are only beginning to discuss what data to collect and how to collect it.

It’s sometimes hard to explain to somebody why regenerative is better. I worked on a ranch that was conventionally managed for 20 years, and five years later, we saw a significant change in so many different things — all the typical things that everybody sees: water infiltration, soil organic matter, etc. But what I saw myself was healthier, happier animals and employees, and more biodiversity. You just can’t relate that to somebody very easily in conversation, and it doesn’t really instill confidence in an investor to say, “It just feels great to do regenerative agriculture.”

We need to be able to shine the spotlight on folks that have been doing this work. And it’s working. And here are the successes. And then, I think, to compare that to other things. I think we need to show that juxtaposition — from conventional agriculture to regenerative. We need to point out not just why are we doing it this way, but why conventional is doing it that way.