Greenhouses Cover Nearly Three Times More of Earth’s Surface Than Previously Thought

We have long since become accustomed to enjoying tomatoes, cucumbers, berries and melons year-round. Globally, greenhouse cultivation is increasing rapidly, according to a new study from the University of Copenhagen. The majority of this boom is happening in low- and middle-income countries.

Using satellite imagery and deep-learning algorithms, the researchers mapped the amount of land used for greenhouse cultivation worldwide. Their mapping shows that covered cultivation spans at least 3.2 million acres of the Earth’s surface — nearly three times more than previous estimates.

| The top ten countries’ share of the 3.2 million greenhouse acres worldwide: China (60.4%) Spain (5.6%) Italy (4.1%) Mexico (3.3%) Turkey (2.4%) Morocco (2.3%) South Korea (1.8%) Japan (1.7%) Netherlands (1.4%) France (1.3%) |

Greenhouse cultivation is spread over 119 different countries, of which China accounts for an entire 60.4 percent of the total area. Spain and Italy occupy second and third place, with 5.6 and 4.1 percent of global greenhouse coverage, respectively.

Whereas large clusters of greenhouses in developed nations were established in the 1970s and ’80s, they began to spring up in developing countries two decades later. The trajectory of growth continues in Asia, Africa and Central and South America. Indeed, greenhouses in the Global South account for 2.7 times as much area as in the Global North.

“Greenhouse cultivation has become a global phenomenon and there is every indication that it will continue to expand. Until now however, this phenomenon is rapidly rising under the radar, and we have had large gaps in our knowledge of the dynamics that drive this phenomenon,” said Xiaoye Tong, first author of the research article, which was published in Nature Food.

According to the researchers, China’s dominance in terms of area is probably tied to the country’s socio-economic development. The study found that large clusters of greenhouses are located near metropolitan areas.

“The boom in China seems to be closely linked to its strong economic performance over the past decade and the rise of an urban population with purchasing power that demands tomatoes, cucumbers and other types of fresh fruit and vegetables,” said Xiaoye Tong. “At the same time, farmers who would otherwise be unable to finance this form of cultivation receive government subsidies and support to build greenhouses and learn cultivation techniques.”

Government support for greenhouse growers doesn’t just exist in China — it is found in arid and semi-arid regions that have traditionally not been cultivated intensively, if at all. Indeed, half of all areas with greenhouse cultivation are in regions with major resource limitations, such as water scarcity. As such, the researchers point out that greenhouse cultivation provides opportunities for local food security and the alleviation of poverty. Due to their controlled environments, greenhouses potentially offer a range of major advantages in the form of higher and more stable yields, efficient irrigation systems, the more precise dosing of fertilizers and nutrients, and improved control of crop quality.

But there is another side to the story. “We know very little about the environmental and social consequences of greenhouse cultivation in the Global South,” said co-author Marianne Nylandsted Larsen. “But we do know that these can include the overexploitation of water resources, high energy consumption, the contamination of groundwater with pesticides and fertilizers, soil degradation and plastic pollution from greenhouses that make use of plastic film and sheeting. Furthermore, agricultural working conditions have often been criticized.”

A Goodyear for Tires … But a Bad Trend for Vegetable Eaters

Residues from drugs and plastics from all sorts of products have recently been found in commercially sold fruit and vegetables all over the world. However, chemical additives from vehicle tires also find their way into the food chain. This has been demonstrated in a new study by researchers at the University of Vienna, in collaboration with a team from the Hebrew University of Jerusalem. Their results were published in Frontiers in Environmental Science.

Car tires consist of a complex mixture of materials that improve their performance and durability. These include 5-15 percent chemical additives, including antioxidants, antiozonants, vulcanizing agents, anti-aging agents and many more. These are added to natural and synthetic rubber to enable the high-tech performance of modern tires.

The compounds extracted from car tires find their way into agriculture through atmospheric deposition, irrigation with treated wastewater, and the use of sewage sludge as fertilizer. From there they can be taken up by plants and into the human food system.

After analyzing vegetables in Austria and Israel, the researchers extrapolated to determine the intake per day based on what people in Switzerland and Israel consume. The concentrations of the tire additives in leafy vegetables are low overall — for example, 238 nanograms/kilogram for benzothiazole. Yet they do contain 0.4 ng/kg of 6PPD, a substance whose transformation product, 6PPD quinone, is known to be highly toxic for aquatic species like coho salmon. Depending on the diet, this leads to a daily intake per person of 12 to 1,296 ng of BTZ, or 0.06 to 2.6 ng of 6PPD. This is comparable in magnitude to drug residues, which also enter the food chain.

According to researcher Thilo Hofmann, the study shows clear results: “While the concentrations and daily intake are fortunately relatively low, additives from car tires are still found in food. That’s not where they belong.”

Frequent Mowing Puts Poisonous Weed in Survival Mode

A study of the effects of mowing on a common weed has found that what doesn’t kill you can make you stronger. The research, published in Nature Scientific Reports, has found that frequent mowing of Solanum elaeagnifolium may help create a “superweed.”

Solanum elaeagnifolium — also known as silverleaf nightshade — can be found from south Texas to South Africa and Greece, infesting fields and soaking up valuable nutrients intended for cash crops. The weed with purple flowers, or sometimes white and light purple, has prickly spines and poisonous berries.

Bottom of Form

Although studies have often highlighted weed fitness and defense traits resulting from disturbances like mowing, most were limited to foliar, or leaf, defenses. Yet the research team from the University of Arkansas monitored fields of mowed and unmowed fields of silverleaf nightshade in and around Edinburg, Texas, in order to determine how the flowers differed — and whether that had any consequences for the insects that feed on them.

The team found that the more silverleaf nightshade was mowed, the more it developed ways to avoid destruction. The taproot went down further — nearly five feet deep — in the first generation of mowed plants. More spikes popped out on the stem as a defense against caterpillars feeding on the flowers. The flowers became more toxic to caterpillars, leading to less pressure from natural predators.

Like time bombs, the plant produced some groups of seeds that germinated faster and others that were delayed. This “staggered” germination was the plant’s way to ensure survival over the long haul, the team believes.

“You are trying to mow these plants so that the plants are getting eliminated,” researcher Rupesh Kariyat said. “But what you are actually doing here, you are making them much worse, much stronger.”

Tilling areas with silverleaf nightshade also spreads the plant because the rhizomic roots, like many weeds, can propagate asexually over multiple years and growing seasons. Since the studies focus solely on silverleaf nightshade, Kariyat said other weeds — even the plant’s family relatives — may or may not react the same way to frequent mowing. However, the study does provide more insight into the defensive capabilities of plants pitted against human disturbance.

“This should be something that we consider when we make management plans,” Kariyat said of the plant’s defenses. “Management practices need to be better understood using the ecology and biology of the species and the other species which interact with them.”

Improved Refrigeration Could Save Nearly Half of the 1.3 Billion Tons of Food Wasted Each Year Globally

About a third of the food produced globally each year goes to waste, while approximately 800 million people suffer from hunger, according to the U.N.’s Food and Agriculture Organization.

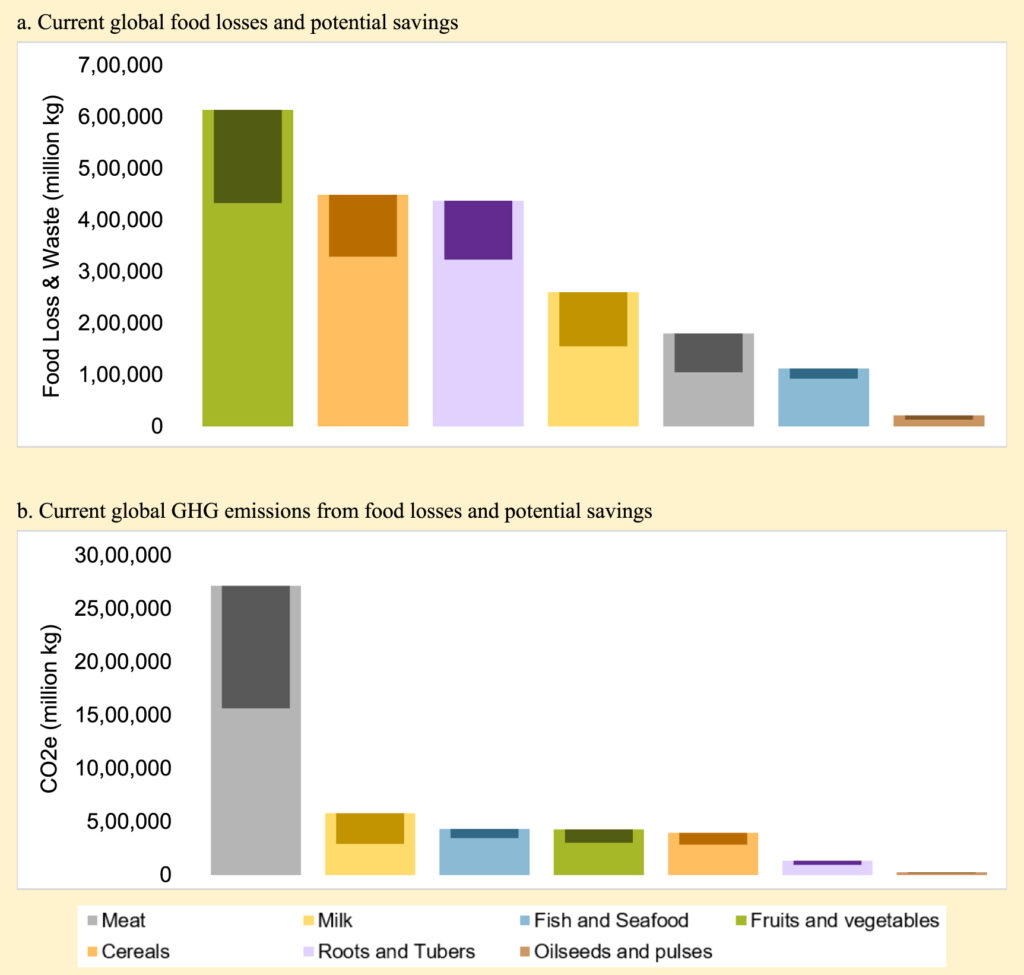

A new University of Michigan study concludes that nearly half of that food waste — about 620 million metric tons — could be eliminated by fully refrigerated food supply chains worldwide. At the same time, fully refrigerated supply chains, or “cold chains,” could cut food waste-related emissions of climate-warming greenhouse gases by 41 percent globally, according to the study published in Environmental Research Letters.

Sub-Saharan Africa and South and Southeast Asia have the greatest potential for reductions in both food losses and related emissions through increased cold-chain implementation, according to the study. South and Southeast Asia could see a 45 percent reduction in food losses and a 54 percent decrease in associated emissions under an optimized refrigeration scenario. Sub-Saharan Africa has tremendous opportunities for both food loss (47 percent) and emissions reductions (66 percent) under optimized refrigeration conditions, the study shows.

Also, in many situations, developing more localized, less industrialized “farm-to-table” food supply chains may yield food savings comparable to optimized cold chains, according to the study.

“I was surprised to find the scale of our opportunity for reducing food loss and waste globally,” said study lead author Aaron Friedman-Heiman. “Approximately half of the roughly 1.3 billion tons of food that goes to waste annually can be solved through food supply-chain optimization.”

Food losses produce an estimated 8 percent of human-caused greenhouse gas emissions. The focused on food losses in the post-harvest to retail stages of the food supply chain and did not address on-farm or at-home losses.

The researchers accounted for the greenhouse gases emitted during food production. They did not include emissions tied to refrigeration or other supply-chain operations and did not include emissions from food waste in landfills.

The study, funded in part by Carrier Global Corp., found that:

- The greatest opportunity to improve food losses in less industrialized economies is the supply chain between the farm and the consumer. But in North America, Europe and other more industrialized regions, most food loss happens at the household level, so cold chain improvements would not have a major impact on total food losses.

- Reinforcing previous research, the study highlights the importance of meat-related food losses. While the amount of fruit and vegetable losses is much higher, by weight, throughout the world, the climate-related emissions associated with meat losses are consistently greater than those associated with any other food type — due mainly to the high greenhouse gas intensity of meat production.

- Unlike previous studies of this topic, researchers compared the benefits of globalized, technologically advanced food-supply chains with those of localized “farm-to-table” food systems. “Hyper-localized food systems resulted in lower food losses than optimized global, refrigerated supply chains,” said Friedman-Heiman. “The results help quantify the value of maintaining and supporting local food chains.”

The researchers emphasized that the actual amount of greenhouse gas emissions savings will depend on the efficiency of cold-chain technologies and the carbon intensity of local electrical grids, since climate emissions associated with refrigeration can be significant.

Harnessing the Full Potential of the Cocoa Fruit

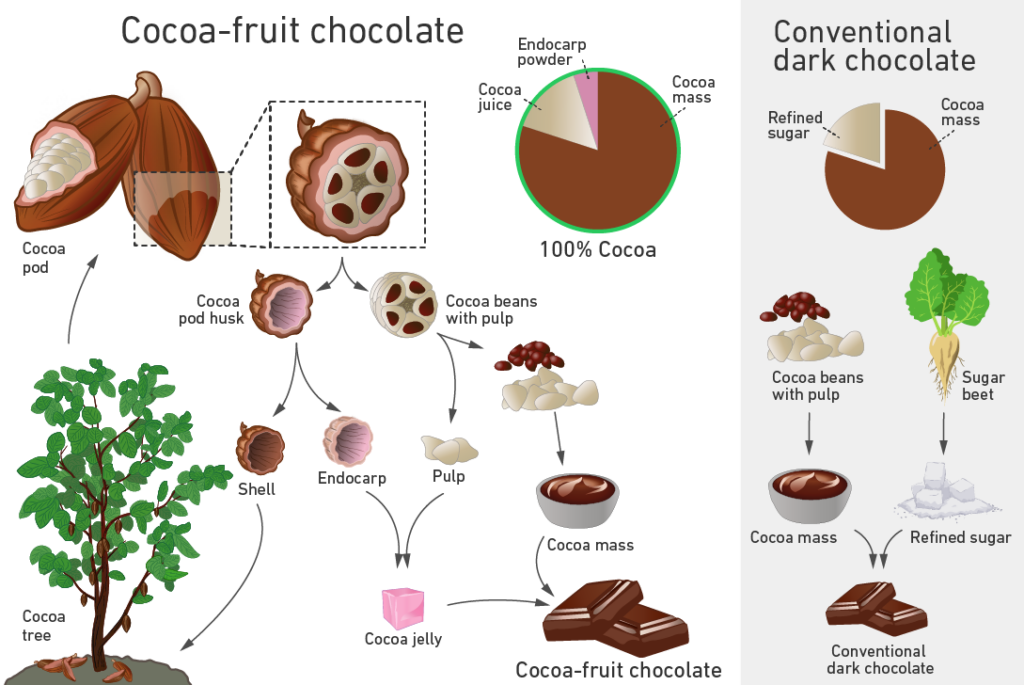

Chocolate is a sweet delight: its main components are cocoa beans and cocoa butter, both of which are extracted from the cocoa fruit. What many people don’t know, however, is that the cocoa fruit contains additional valuable ingredients that have been underutilized until now.

Researchers at ETH Zurich have joined forces with the chocolate industry to investigate the potential for making maximum use of the cocoa fruit in an effort to increase the profitability of cocoa cultivation — while also making chocolate a healthier indulgence.

Kim Mishra, main author of the Nature Food study, says that the cocoa fruit is similar to the honeydew melon. “These fruits have similar structures. Both have a hard outer shell that reveals the flesh of the fruit when cut open, as well as the cocoa beans or melon seeds and pulp in the interior.” Conventional chocolate only makes use of the beans, but the researchers were able to use the flesh and parts of the fruit shell — or the endocarp, to use the field-specific term — for their cocoa-fruit chocolate recipe. They processed it into powder and mixed it with part of the pulp to form cocoa gel. This gel substance is extremely sweet and can replace the added powdered sugar that is normally part of the chocolate-making process.

It was not easy for the scientists to find the perfect recipe for cocoa-fruit chocolate. They systematically tested the texture of various compositions in the lab. Too much fruit juice extracted from the pulp made for a clumpy chocolate, but too little resulted in an insufficiently sweet product. The issue with clumping does not arise when using powdered sugar. The experiments showed that chocolate may contain up to 20 percent gel, which is equivalent to the sweetness of chocolate with 5 to 10 percent powdered sugar. In comparison, conventional dark chocolate can easily contain between 30 and 40 percent powdered sugar.

By using cocoa gel as a sweetener, cocoa-fruit chocolate boasts a higher fiber content than the average European dark chocolate (15 grams versus 12 grams per 100 grams). It also contains only 23 grams of saturated fat as opposed to the usual 33 grams.

Small-scale farmers can diversify their product offerings and increase their income if other components of the cocoa fruit can be marketed for chocolate production instead of just the beans. And if most of the fruit can be used to produce cocoa-fruit chocolate, only the shell remains, which is traditionally used as fuel or composting material.

This doesn’t mean that cocoa-fruit chocolate will be hitting grocery store shelves anytime soon, however. “Although we’ve shown that our chocolate is attractive and has a comparable sensory experience to normal chocolate, the entire value creation chain will need to be adapted, starting with the cocoa farmers, who will require drying facilities,” said Mishra. “Cocoa-fruit chocolate can only be produced and sold on a large scale by chocolate producers once enough powder is produced by food processing companies.”

The first step has been taken: ETH has filed a patent for its cocoa-fruit chocolate recipe. The development of cocoa-fruit chocolate is a promising example of how technology, nutrition, eco-compatibility and income diversification for small farmers can all work in tandem to improve the entire value-creation chain of the cocoa plant.