Make your operation both more regenerative and profitable

Good equipment makes farming fun. Inadequate equipment can make it frustrating and unprofitable.

These are just some of the many innovations that are currently available to regenerative farmers — or that soon will be.

In-row Roller-Crimpers

One of the biggest innovations in no-till farming in recent decades is the roller-crimper — a large wheel that rolls in front of or behind a tractor and crimps (not cuts) a cover crop such as rye or vetch in order to kill the plant but leave the residue. Cash crops are then planted into this residue with a no-till planter.

In-row roller-crimpers take this concept to the next level by allowing growers to selectively roll/crimp cover crops and/or weeds between rows of cash crops. They allow farmers to plant and roll at optimal times — rather than having to do one or the other at a time that’s not quite ideal. This is often the case with soybeans, which are often better planted before cereal rye is ready to roll.

Growers can also roll multiple times. “This summer I even rolled beans all the way up to when they were three foot tall,” says Iowa farmer Loran Steinlage. “It gives you a totally new tool to manage the options.”

The InRowl by Dawn Equipment and Underground Ag is one example of this new technology. It comes in varying widths, from 15 to 40 inches, and there are deflector plates on the side of each roller. This means that early in the season, the rolled material can swath out over the seed row, and later in the season it can be made to lie down between the rows and not hurt the cash crop.

InRowl utilizes hydraulic pressure control to apply 0 to 700 pounds instantly. While this will add maintenance concerns, it allows for more precise and adjustable application of pressure than simple weights.

Sulfur Burners

Water quality is of utmost importance for growers — especially for high-value vegetables and fruits. High levels of water hardness — in particular, bicarbonates — can significantly reduce the efficacy of fertilizer and foliar treatments.

For foliar feeding, which requires especially pure water, see the next section on reverse osmosis treatment. For general irrigation water, though, the best way to reduce hardness is via sulfur burners.

Sulfur burners are the organic replacement for sulfuric acid injectors. Sulphuric acid injectors incur safety issues, and elevated application rates can have a long-term detrimental effects on soil biology.

A sulfur burner consists of a series of vessels into which a grower simply adds powdered elemental sulfur. When the irrigation system turns on, it automatically partially fills a tank with water, introduces the powdered elemental sulfur, and burns it with an electric arc in the water solution to create sulfurous acid — instead of sulfuric acid. Elemental sulfur is half the price of sulphuric acid, and it’s a lot safer to handle. It’s also permitted under organic certification, and it’s friendly to soil biology — sulfurous acid has the effect of stimulating biology rather than suppressing it.

Sulfur burners do require a significant upfront capital investment, but given the elevated price of sulfuric acid and elemental sulfur, they become affordable very quickly.

Reverse Osmosis Systems

As described above, water quality is of key importance — especially when foliar feeding.

High levels of bicarbonates can greatly reduce the effectiveness of foliar feeding. Bicarbonates above 120 ppm definitely need to be addressed; below 80 is best.

Osmosis occurs when a solution of low concentration moves through a semi-permeable barrier to get to an area of higher concentration. Reverse osmosis puts pressure on the water to go the opposite way. The result is water that is free of most everything — including bicarbonates.

RO systems are too expensive and have too low of throughput to be an option for irrigation on most operations. But they’re a great way to obtain pure water for higher-cost/higher-impact foliar feeding applications. Getting below 80 ppm of bicarbonates may mean simply mixing some RO-produced water with well water or captured rainwater.

Prone Harvesters

Most market farmers do a great job of focusing on the resiliency of their farm business — their financial strength, their ability to produce in varying climatic conditions and their plan to have their business survive into the future. This last point is particularly important in regard to the farmer’s physical ability to keep going year after year. On her podcast, Clara Coleman always asks each guest, “How are you going to keep farming growing old?”

One relatively low-tech solution for some growers may be a prone harvester: a motorized cart that can move slowly down a row carrying a worker who is lying belly down, but with the head supported and both hands free. This enables any field task, from hand-picking weeds, to transplanting, to harvesting challenging crops like strawberries or green beans — all while keeping the back straight.

While prone harvesters have been used for a long time in large-scale commercial growing — particularly to pull a number of strawberry pickers behind a tractor — several producers have come up with single- or double-row versions for the smaller market farm. These include Nessa, Inc., and Terrateck.

Ergonomics are incredibly important in modern life, and farming is no exception. Prone harvesters offer the possibility of continuing to farm longer by reducing how time much the grower spends bent over in the field.

Sheep Bulk Handler Systems

Anyone who has worked sheep knows how physically demanding such work can be. Even low-stress operations require a huge amount of time bending over and wrestling with sheep to get them into position for various husbandry operations.

ProWay, an Australian livestock equipment company, offers a bulk sheep handler that greatly simplifies these procedures on a larger sheep operation. Their bulk handler — available in 6- and 12-meter lengths in static or mobile configurations — is more than just a raceway that confines sheep in a narrow corridor. On the bottom of their raceway is a series of pipes that the sheep step over; once trapped inside the raceway, the operator activates a hydraulic pump that lifts the entire raceway. The bars come to rest under the sheeps’ bellies and they are suspended a few inches in the air, unable to move. Once done with treatments, the operator lets the raceway back down and the sheep can move out.

While the feasibility of such equipment obviously depends on scale, this is a simple technology that would surely benefit larger sheep operations.

Drones for Seeding and Spraying

Given the limited volume of either seed or liquid that a drone can carry, it’s easy to understand how someone would be skeptical of this idea.

However, consider a field that has been determined via satellite or aircraft imagery — or simple physical crop scouting — to have a small patch that needs either reseeding or a foliar application that differs significantly from the rest of the field. Getting a tractor into a 100-acre field to reseed or fertilize half an acre is impractical, if not impossible. Airplanes are likely not accurate enough, and piloted helicopters are expensive. Drones can be a feasible option in such a scenario.

There are various companies beginning to offer drones for spraying and seeding. Rantizo, for example, has versions that can be outfitted with a 14-foot boom and that can carry up to eight gallons. Some companies sell the equipment and others offer services.

Drones are obviously not cheap, and one must also consider licensing, insurance and technical support. Cybersecurity should not be forgotten, either — DJI, which has about 70 percent of the drone market share worldwide, is a Chinese company and thus must make all its data available to the Chinese Communist Party. But drones are an option that may fit some growers’ context.

Between-row Robots for Seeding and Spraying

Robots on the farm are just as unique as drones, and they’re now also being used for seeding and spraying in-between rows. The scenario to consider is similar to that for drones — not huge fields, but small areas of huge fields that need attention and are difficult to access with common farm equipment.

Robots have higher carrying capacity than drones — up to 20 or 30 pounds of seed or amendment in the case of the RowBot. They move autonomously via sensors to pre-programmed areas of the field and plant cover crops or apply liquid amendments as needed. They can also be useful in corners of fields that are difficult for tractors to get to. In certain relay cropping scenarios, the grower may not really have a place to drive a tractor; losing yield to tires is certainly not ideal.

Robots with drills also offer seed-to-soil contact that broadcast seeding — whether from a drone or an airplane or helicopter — can’t accomplish.

Grounded robots face similar challenges as drones — primarily, technological sophistication that requires outside support and cost.

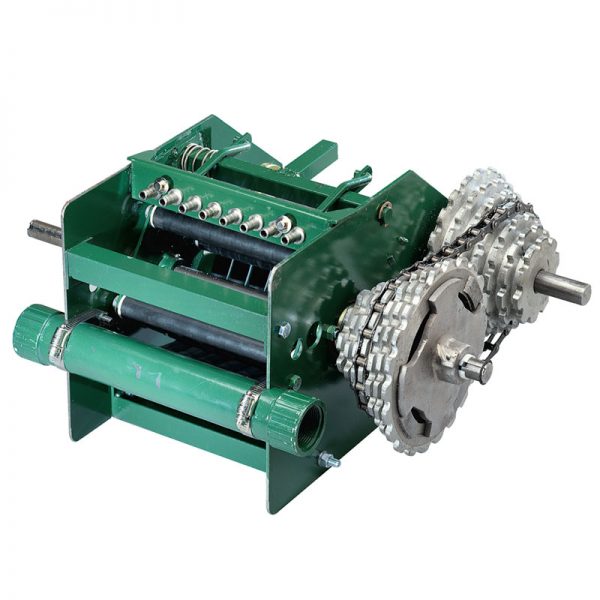

Planter Squeeze Pumps

Squeeze pumps are old technology that are perhaps underappreciated today.

Most modern pumps apply liquid solution into a hole or furrow at fairly high pressures — anywhere from 40 to 100 pounds. To maintain application rates from a range of three to eight gallons per acre — which is common — requires pin-sized holes.

But there are problems with this from a biological agriculture perspective. The high pressure has negative impacts on biology. Also, biological materials like liquid fish and humic substances have difficulty with small nozzles.

Squeeze pumps solve these problems. They have a piece of tubing connected to each nozzle that is massaged by a set of rollers and is driven by a ground wheel. When the planter goes faster or slower, it adjusts automatically and produces steady drips of amendment at very low pressure. This is very friendly to biology.

Squeeze pumps are basically unclog-able. Any type of biological material can go through it — even large molecules like mycorrhizal fungi that high-pressure streams will damage.

For growers who have an interest in applying biological products — whether that be compost teas, mycorrhizal fungi, or simply liquid fish and humic acid — a squeeze pump is a low-tech, wise investment.

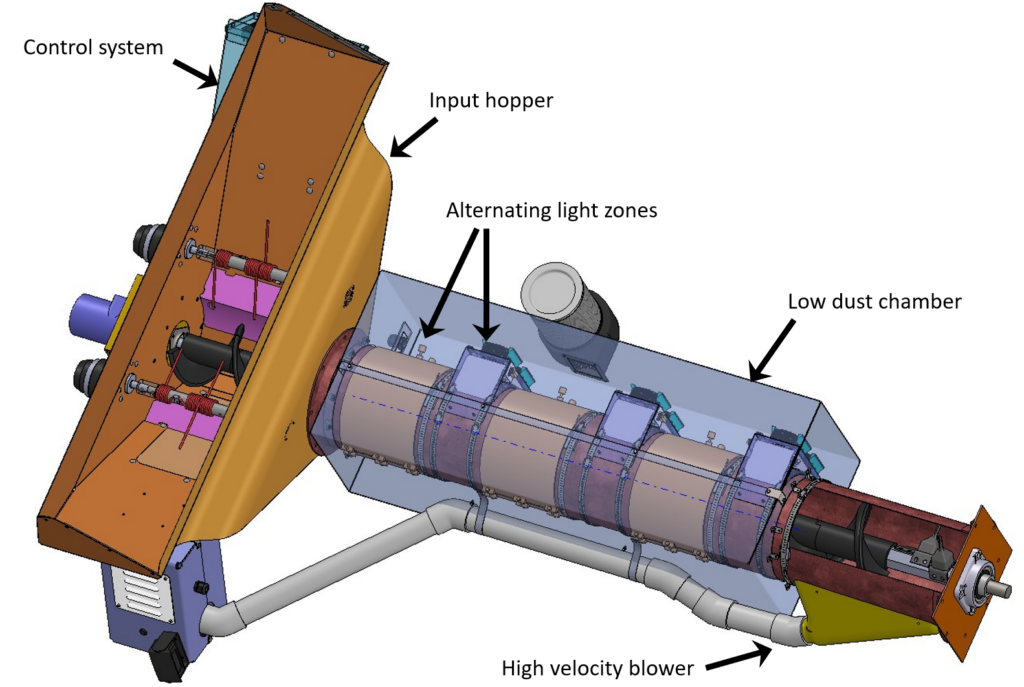

Weed-seed Destroyers

Grain fields of all types contain weeds, no matter how good a job a grower does in preventing them. When fields are combined, they pick up these weeds and sort out the weed seeds, which are then spit back out onto the ground.

What if these seeds could be destroyed, or rendered infertile, before returning to the field — in order to decrease the latent seed bank?

Some growers use mechanical impact mills that turn all of the chaff and weed seeds exiting the combine into a flour. These devices are expensive, though, require fairly significant maintenance and use 60 to 100 horsepower to operate.

A new solution to this problem that is expected on the market in 2023 is a directed-energy device manufactured by Global Neighbor. Their solution is to first expose the chaff and weed seeds to mid-range infrared light, which is absorbed by the seed but is transparent to the chaff; the material then goes through an auger, in which it is exposed to a very intense blue light. The combination of these two wavelengths at precise intensities makes it so that the weed seeds are unable to germinate.

Global Neighbor’s weed seed destroyer is about half as expensive and requires much less maintenance than the mechanical alternative, and it uses just 10 horsepower to operate.