Ethanol, peak oil and the energy transition

“Corn … The Future.”

I quickly glanced at the slogan and image of a giant corn cob emblazoned on the awaiting “corn car,” then climbed inside, along with a couple other college students. Our guide hopped into the driver’s seat, pulled into a nearby gas station to fill the tank with E-85, and drove us a few minutes down the road to our destination — an ethanol plant.

Armed with hard hats, earplugs, and safety glasses, our group followed a tour guide through the factory. We saw piles of dried distiller’s grains (DDGs), which had a pleasant, fermented odor. We passed giant, shiny tanks and pipes. We went through a noisy, echoing room full of hammer mills. Then we stepped back outside into the bright October sunshine.

“It’s so much cleaner and nicer than an oil refinery,” one of my fellow students remarked. Our tour guide assured us that corn ethanol, produced at dozens of plants like this across the United States, was making a huge contribution to the American energy supply. Ethanol was much cleaner and safer than other gasoline additives, like xylene. And besides, if 40 percent of the nation’s corn crop wasn’t used to make ethanol, what would we do with the surplus? It seemed like the perfect solution to both the energy and agricultural surplus problems.

But was it? Could ethanol ever really power the American transportation system?

Peak Oil?

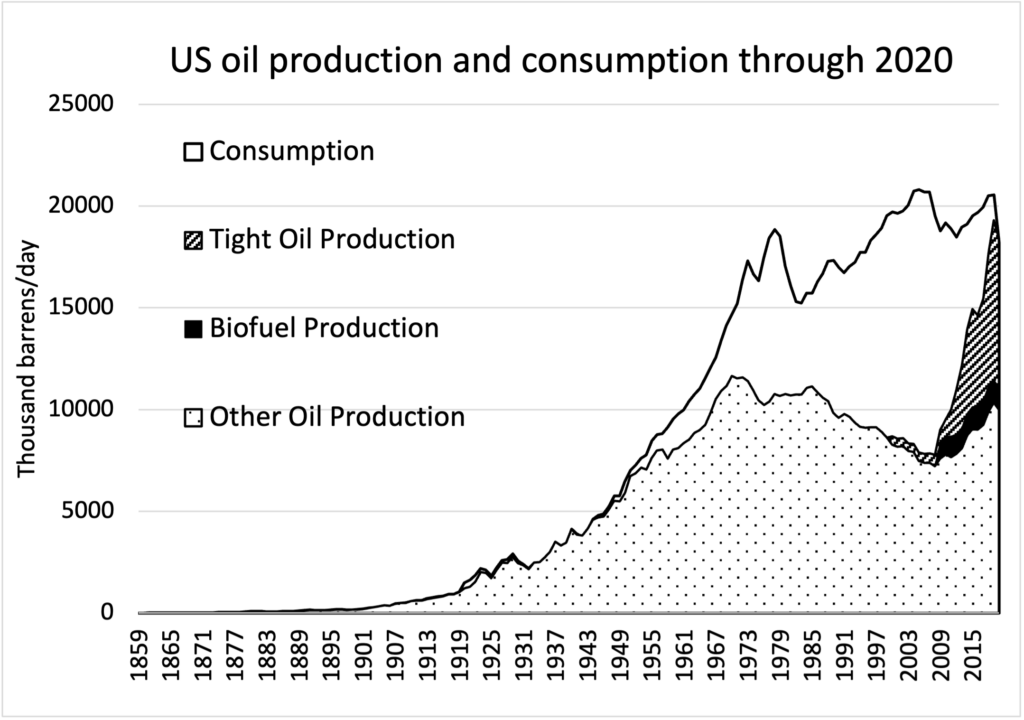

Ever since the invention of the gasoline-powered automobile, people have worried about what will happen when the world’s limited supplies of fossil fuels are exhausted. In the 1950s, a Shell Oil petroleum geologist named Marion King Hubbert looked at oil production and discovery data and correctly predicted that U.S. crude oil production would peak sometime around 1970. Along with political and economic factors, declining U.S. domestic oil production was one cause of the oil crises in 1973 and 1979.

Government policies in the 1980s addressed the economic causes of the oil crisis by decontrolling oil prices and putting petroleum on the global free market. This, combined with increased U.S. military involvement in the Middle East, helped prevent a recurrence of the Arab oil embargos that had partially contributed to the 1970s crises. By the 1990s, oil shortages were only a distant memory, and American oil consumption continued to rise — but domestic production continued to decline.

In 2005, the United States was importing 62 percent of the oil it consumed — a higher dependence on imported oil, by both volume and proportion, than in the 1970s. Just as had been the case 30 years earlier, few Americans thought about the implications of their dependence on foreign oil — until it hit them at the gas pump.

The free market for oil changed what a supply constraint looked like. There were no lines or shortages at individual gas stations in 2007 like there had been in 1973 and 1979. All that happened as global oil consumption started to meet global supply was that gas prices began to rise — from about $1.50 a gallon in 2003 to $4 a gallon in June 2008, according to the U.S. Energy Information Administration (EIA).

When oil prices began to rise in 2005, a small group of both popular and academic writers began expressing concerns about “peak oil.” They looked back at Hubbert’s predictions and pointed out that he had been almost exactly right about the peak of conventional crude oil production in the continental U.S. Regardless of how much oil the world actually contained, it seemed only logical to conclude that the supply was finite. Sooner or later, every oil-producing country would reach peak production, just like the U.S. had in 1970. And at some point, global oil production would also peak. The only question remaining was when.

Many people believed that conventional crude oil production was right at this peak sometime between 2005 and 2008 and that this supply constraint was causing prices to rise. More optimistic projections put the peak back as far as 2030 or even 2040, but everyone who wrote about peak oil agreed that the global all-oil peak would be reached sometime before the middle of the 21st century.

The good news, Kjell Aleklett and Michael Lardelli pointed out in their 2012 book Peeking at Peak Oil, was that if they were even close to being right about an impending peak in oil production, the worst-case climate change scenarios modeled by the IPCC were impossible because they were based on burning about four or five times more coal and oil than could probably ever be recovered.

While they disagreed about the quantity of ultimately recoverable fossil fuel reserves, peak oil and climate change modelers agreed about one thing — the need for an imminent transition to renewable energy. Wind, solar, hydropower and biomass were the leading renewable energy candidates in the early 2000s.

But most renewable energy sources could only be used to generate electricity, and thus they could not directly substitute for oil in transportation. The only practical substitute for gasoline in existing engines was still the same as it had been a century earlier — corn ethanol. And so began the biggest push for ethanol production in American history.

The Rise of Ethanol

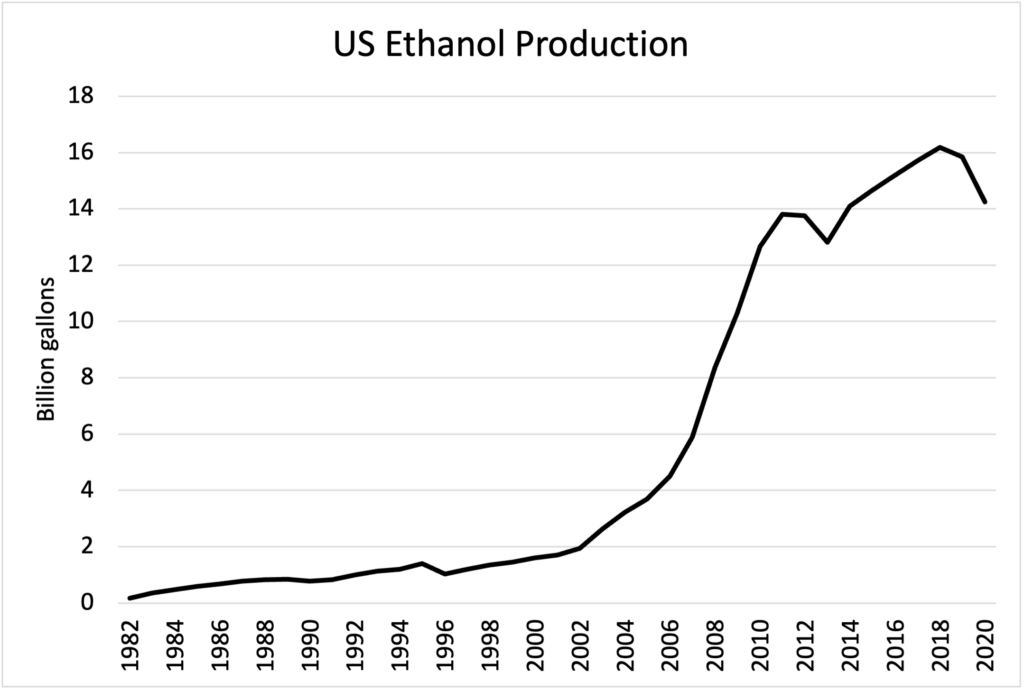

The American fuel ethanol industry started during the 1970s oil crises and grew slowly and steadily each year, despite little public interest in renewable energy. According to the EIA, U.S. ethanol plants increased production from 58 million gallons of ethanol in 1985 to 3.7 billion gallons in 2005.

Ethanol production was already following an exponential growth curve before Congress passed the Energy Policy Act of 2005, which mandated that a minimum amount of biofuels (mostly corn ethanol) be blended into gasoline.

The Energy Independence and Security Act of 2007 raised these minimum requirements even higher, mandating that ethanol production increase from 4 billion gallons in 2006 to 30 billion in 2020. In addition, this legislation placed a cap of 15 billion gallons a year on corn ethanol; the rest of this increase had to come from “advanced” cellulosic biofuels made from non-food energy crops like switchgrass.

Corn ethanol, already trending upward, followed these mandates almost exactly until 2011. In that year, 5 billion bushels of corn (38 percent of the entire U.S. corn crop) was used to make 14 billion gallons of fuel ethanol. But a cellulosic ethanol industry failed to materialize, despite the economic incentive provided by the government mandate. With far less fanfare than the original legislation, the EPA quietly reduced the cellulosic and total ethanol mandates from 2010 on.

Corn ethanol production rose to a peak of nearly 16 billion gallons in 2018, continuing to use about 40 percent of the U.S. corn crop. But the previously exponential growth curve leveled out when ethanol reached the “blend wall” in 2016. All gasoline in the United States now contained 10 percent ethanol, which was the most that could be used in older vehicles without voiding the manufacturer’s warranty. From 2016 on, ethanol production has been tied to gasoline consumption, and the drastic drop in travel during the April 2020 COVID-19 lockdowns also reduced the demand for ethanol.

Producing this volume of renewable fuels was a remarkable achievement, and ethanol boosters — like the operator of the plant I toured — were proud of doing their part to help meet America’s energy needs. But not everyone agreed that ethanol was really decreasing total energy consumption.

The Net Energy Debate

Ever since the late 1970s, scientists from various disciplines have tried to determine the “net energy value” or “energy balance” of ethanol. Modern corn farming and industrial ethanol production use significant amounts of fossil fuel energy — to produce fertilizers, power tractors, transport grain by truck or train, and distill fermented corn into 200-proof alcohol. The question for 40 years has been, Does it take more, less, or the same amount of energy to make ethanol as is gained from burning it?

As ethanol production started to rise in the early 2000s, the net energy debate was revived. On one extreme was David Pimentel, a professor of ecology and agricultural sciences at Cornell University. Pimentel calculated in a 2003 article for Natural Resources Research that it took 20 to 29 percent more energy to make a gallon of ethanol that was gained by burning it — a net energy ratio of -1.29 to 1.

On the opposite extreme, USDA economist Hosein Shapouri and others calculated in their 2002 USDA bulletin The Energy Balance of Corn Ethanol: An Update that ethanol had a positive energy balance, with a net energy ratio of 1.34. Shapouri regarded Pimental’s calculations as overly pessimistic because he included the embodied energy used to construct ethanol plants and farm machinery. Pimentel in turn argued that ethanol proponents gave too much energy credit to the dried distiller’s grains (DDGs) created as a byproduct of the ethanol manufacturing process.

Not surprisingly, ethanol plants constructed during the 2000s and 2010s were more efficient than the prototype plants upon which these turn-of-the-century calculations had been based. Studies conducted between 2009 and 2014 mostly agreed that the average net energy ratio for U.S. ethanol plants was somewhere around 1.5 — a number that is unlikely to improve in the near future now that the boom of new ethanol plant construction has declined. That means that it takes about two units of energy inputs to produce three units of energy from ethanol — or that one gallon of ethanol only displaces a third of a gallon of gasoline.

Although most researchers assumed that a positive net energy value was enough justification to promote ethanol, Charles Hall, David Murphy, and other environmental researchers at the State College of New York disagreed. They applied the concept of energy return on investment (EROI) to calculate what they believed was the minimum net energy ratio it would take to not only power the nation’s automobiles, but to maintain the entire transportation infrastructure. In a 2009 article for Energies, Hall and others calculated that a primary fuel with an EROI of at least 3 was required to maintain the transportation system — more than even the highest values estimated for ethanol. They estimated that American industrial civilization as a whole could only function on a primary fuel with an EROI of 5 or greater.

In other words, even if it was possible to multiply corn production tenfold, ethanol could never replace gasoline in the current transportation system. The reason that ethanol was never a serious contender with gasoline was because of its low EROI — it has always been more expensive both in monetary and energy terms.

The hard reality is that most of our current transportation and agricultural infrastructure can only function as long as oil is cheap. Tractors, synthetic nitrogen fertilizer and semi-trucks on the interstate highways all rose to prominence during the age of cheap oil. The system as we know it today has never functioned without petroleum, and there is no assurance that it could run on any other energy source. The transition to renewable energy might not be as simple as merely substituting one fuel for another — it might mean a complete redesign of the American food system.

The good news is that we still have some time to make that transition. Contrary to most of the predictions from 2005, we haven’t reached global peak oil yet. In fact, to almost everyone’s surprise, U.S. domestic oil production increased by two and a half times between 2005 and 2019, surpassing the previous peak in 1970 and allowing the U.S. to become a net exporter of oil in 2020!

This historic event had nothing to do with ethanol or other renewable energy. It was caused by breakthroughs in hydraulic fracturing technology (fracking) that suddenly made previously uneconomical “tight oil” deposits in shale formations lucrative to extract. Tight oil from fracking made up 65 percent of U.S. oil production in 2020 and is the main reason that discussions about peak oil dropped even faster than gasoline prices during the 2010s.

But if there is any value to the concept of peak oil, those discussions are more important now than ever.

Rethinking the Food System

The shale oil boom threw off peak oil calculations by at least a decade or two, but newer peak oil models that take tight oil into account still predict a peak by 2040. Maybe they’ll be right; maybe not. Many climate scientists believe that oil consumption should peak soon whether or not supplies are constrained because of concerns about the contribution of fossil fuel combustion to climate change.

Either way, it’s time to take a hard look at what kind of changes will need to take place in transportation and agriculture to lessen our dependence on petroleum. We need to realize that our current food production and distribution system was built on cheap oil and that as oil starts to get expensive (which is what will happen when supplies get constrained in a free market economy), it will be harder to maintain the current infrastructure.

But that’s not necessarily a bad thing. As eco-ag proponents have been pointing out for fifty years, excessive energy consumption isn’t the only thing wrong with the modern American food system. Soil erosion, nutrient pollution from excessive fertilizer use, toxic pesticides, loss of family farms, and disconnection of consumers from their food supply are only some of the negative consequences of industrialized agriculture.

“Our jet-age dependence on petroleum to feed our faces is a limited-time-only proposition,” Barbara Kingsolver warned in her 2007 book Animal, Vegetable, Miracle. At the height of concern about peak oil, Kingsolver and her family moved from arid Arizona to a small farm in Virginia, where they grew much of their own meat and vegetables and purchased the rest from other local farmers. Her book and others stimulated a huge interest in local, seasonal food and the possibility of developing regional alternatives to the global food system.

Local food networks, combined with eco-agriculture practices, can drastically reduce agriculture’s dependence on petroleum. Raising beef and dairy cattle using a management-intensive grazing system could convert many acres of cornfields that are currently going into ethanol and animal feed into soil-building grasslands. Producing fruits and vegetables using organic methods could cut back on both the energy wasted in producing nitrogen fertilizers and the water pollution caused by using them. And selling these products locally could help revive struggling rural communities and support more farmers on the same amount of land.

Change won’t happen overnight, but the fracking boom has bought us enough time to get an alternative system in place before industrial agriculture collapses. If we plan appropriately and develop lower-energy, local food systems now, the transition to a low-energy future may be so seamless that we hardly notice when peak oil actually happens.

Is corn the future? Certainly. But maybe it won’t be ethanol — maybe it will be fresh, local sweet corn!

Anneliese Abbot is a graduate student in the Nelson Institute for Environmental Studies at the University of Wisconsin-Madison. She is the author of Malabar Farm: Louis Bromfield, Friends of the Land, and the Rise of Sustainable Agriculture. She can be contacted at amabbott@wisc.edu.